Wenn es um Verpackung geht, Versand, und Lagerung, Die Begriffe Karton und Wellpappe werden oft synonym verwendet. Jedoch, Diese beiden Arten von Boxen unterscheiden sich hinsichtlich ihres Aufbaus stark, Stärke, und Nutzung. Wenn Sie ihre Unterschiede kennen, können Sie die richtige Lösung für Ihre Verpackungsanforderungen auswählen – sei es für die leichte Präsentation im Einzelhandel oder für den Schwerlastversand.

Was ist der Unterschied zwischen einem Karton und einem Karton aus Wellpappe??

Strukturelle Zusammensetzung

- Kartons

Hergestellt aus einem einzigen dicken Blatt Pappe. Es ist flach, glatt, und es fehlt jegliche innere Riffelung.

- Wellkästen

Hergestellt aus drei oder mehr Schichten – zwei flache Linerboards, die eine zentrale Riffelung umgeben (wellig) Medium. Dieses Design sorgt für Stabilität und Haltbarkeit.

Gewicht und Stärke

- Karton

Leicht und nicht zum Tragen schwerer Lasten geeignet. Es wird hauptsächlich für Displays und Produktverpackungen verwendet.

- Gewellt

Gebaut, um höherem Druck standzuhalten, damit es für den Versand geeignet ist, Stapeln, und zum Schutz zerbrechlicher oder schwerer Gegenstände.

Flexibilität im Einsatz

- Karton

Einfach zu falten, drucken, und für Marketing- und Brandingzwecke anpassen, aber nicht sehr schützend.

- Gewellt

Vielseitig im Design und branchenübergreifend weit verbreitet, Von der Lebensmittellieferung bis zum Elektronikversand.

Umweltauswirkungen

- Beide Materialien sind recycelbar, Kartons aus Wellpappe sind jedoch tendenziell nachhaltiger, da bei ihrer Herstellung ein höherer Anteil an recyceltem Material verwendet wird.

Was ist eine Wellpappschachtel??

Wellpappkartons sind in vielen Branchen die erste Wahl für Schutzverpackungen. Aber was macht ein Wellpappschachtel etwas Besonderes im Vergleich zu anderen Typen?

Geriffeltes Medium zur Polsterung

Die wellige Schicht (geriffelt) zwischen den beiden Linerboards fungiert als Stoßdämpfer, Dadurch wird die Box widerstandsfähiger gegen Quetschungen und Stöße während des Transports.

Haltbarkeit und Steifigkeit

Kartons aus Wellpappe sind aufgrund ihres geschichteten Aufbaus deutlich stabiler als Flachkarton. Sie behalten auch unter Belastung ihre Form, Dies ist für den Schutz von Artikeln beim Fernversand von entscheidender Bedeutung.

Vielseitige Anwendungen

Wird im E-Commerce verwendet, Herstellung, Logistik, und Einzelhandel. Von Pizzakartons bis hin zu Großgeräteverpackungen, Wellpappkartons sind überall.

Feuchtigkeitsbeständigkeit

Einige Kartons aus Wellpappe sind wasserabweisend beschichtet oder behandelt, Sie eignen sich daher ideal für verderbliche Waren oder die Lagerung in feuchten Umgebungen.

Kostengünstig in großen Mengen

Obwohl sie teurer erscheinen mögen als Pappe, Wellpappkartons bieten aufgrund ihrer Schutzeigenschaften langfristig einen besseren Wert, Reduzierung von Produktschäden während des Transports.

Arten von Wellpappenkartons: Die Variationen verstehen

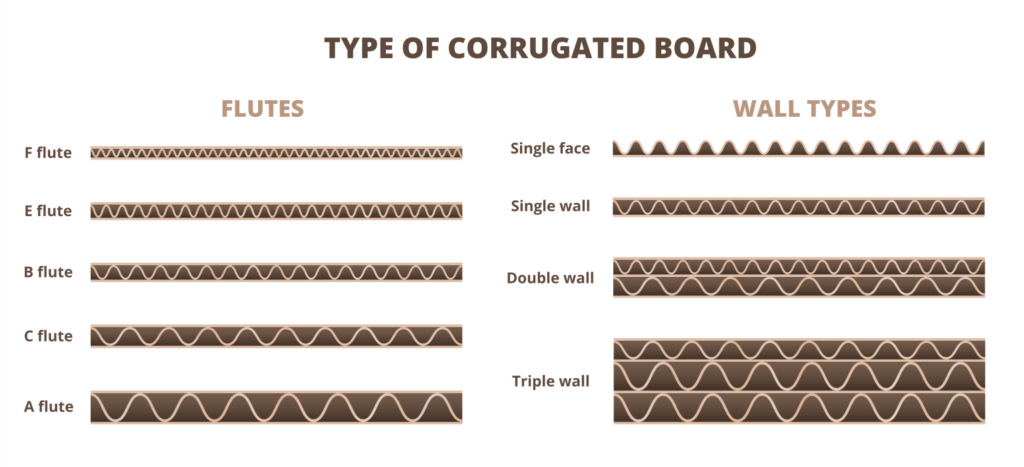

Nicht alle Wellpappkartons sind gleich. Ihre Stärke und Funktionalität hängen von der Anzahl der Wände und der Art der verwendeten Hohlkehle ab. Diese Variationen werden als bezeichnet Arten von Wellpappe.

Einwandige Wellpappkartons

- Bestehen aus einer Lage Riffelung zwischen zwei Linerboards.

- Wird häufig für Standardverpackungen und den Einzelhandelsversand verwendet.

- Geringes Gewicht, aber für mittlere Stapellasten geeignet.

- Ideal für kleine bis mittelgroße Produkte.

- Einfach anpassbar und kostengünstig.

Doppelwandige Wellpappkartons

- Haben Sie zwei geriffelte Medien und drei Linerboards.

- Bieten zusätzlichen Schutz und Steifigkeit.

- Wird für schwerere oder zerbrechlichere Güter wie Elektronik oder Glaswaren verwendet.

- Besser geeignet für den Fernversand.

- Bieten eine höhere Durchstoß- und Kompressionsfestigkeit.

Dreiwandige Wellpappkartons

- Gebaut mit drei Lagen Riffelung und vier Linerboards.

- Bieten maximale Haltbarkeit und Unterstützung.

- Wird in industriellen Anwendungen eingesetzt, beispielsweise beim Transport von Maschinenteilen, Automobilzulieferer, oder Exportverpackung.

- Kann in manchen Fällen Holzkisten ersetzen.

- Hohe Biegefestigkeit, zerquetschen, und platzen.

Wann sollten Wellpappe und Karton verwendet werden??

| Besonderheit | Pappkarton | Wellpappschachtel |

|---|---|---|

| Materialtyp | Einschichtiger Karton | Mehrschichtig mit geriffelter Innenstruktur |

| Ideal für | Einzelhandelsverpackung, Produktpräsentation | Versand, Lagerung, Schutz schwerer Gegenstände |

| Gewichtskapazität | Niedrig bis mittel | Mittel bis hoch |

| Haltbarkeit | Nicht bruchfest | Stark und schlagfest |

| Gemeinsame Industrien | Essen, Kosmetika, Einzelhandel | E-Commerce, Logistik, Industrielle Fertigung |

Verwenden Sie Kartons, wenn:

- Für leichte Produkte: Ideal für Artikel wie Kosmetika, Snacks, oder kleine Elektronik.

- Im Einzelhandelsdisplay: Ideal für Produktverpackungen, die einen hochwertigen Druck und eine ansprechende Optik im Regal erfordern.

- Für Innenverpackungen: Wird oft als Trennwand oder Hülle in größeren Versandkartons verwendet.

- Nahverkehr: Geeignet, wenn der Schutzbedarf minimal ist.

Verwenden Sie Wellpappenkartons, wenn:

- Für den Versand & Lieferung: Stark genug für Langstreckentransporte und grobe Handhabung.

- Für zerbrechliche oder schwere Gegenstände: Schützt Glaswaren, Elektronik, und Industrieteile.

- Im E-Commerce & Logistik: Üblich bei Online-Bestellungen, insbesondere sperrige Güter.

- Für die Lagerung im Lager: Hält Stapelung und Druck bei Lagerung oder Transport stand.

Vor- und Nachteile jedes Boxtyps

Um Ihnen bei der Entscheidung zu helfen, welche Verpackungslösung Ihren Anforderungen am besten entspricht, Hier finden Sie eine Aufschlüsselung der Vor- und Nachteile von Kartons und Wellpappkartons.

Kartons

Vorteile

- Leicht und kompakt: Ideal für Regaldisplays oder Innenverpackungen.

- Kosteneffizient: Günstiger in der Herstellung und im Transport für leichte Produkte.

- Gut für das Branding: Die glatte Oberfläche ermöglicht einen hochwertigen Druck.

- Umweltfreundlich: Vollständig recycelbar und biologisch abbaubar.

Nachteile

- Begrenzte Stärke: Nicht zum Stapeln oder Versenden zerbrechlicher/schwerer Gegenstände geeignet.

- Keine Dämpfung: Bietet minimalen Schutz während der Handhabung oder des Transports.

- Schlechte Feuchtigkeitsbeständigkeit: Leicht beschädigt durch Feuchtigkeit oder Flüssigkeiten.

Wellkästen

Vorteile

- Hohe Haltbarkeit: Hervorragende Druckfestigkeit, Auswirkungen, und Punktion.

- Schützende Polsterung: Die innere Riffelung schützt zerbrechliche Gegenstände.

- Vielzahl von Typen: Einzel, doppelt, und dreiwandige Optionen für unterschiedliche Anforderungen.

- Nachhaltigkeit: Oft mit hohem Recyclinganteil hergestellt und vollständig recycelbar.

Nachteile

- Bulker: Nimmt mehr Platz in der Lagerung ein.

- Etwas höhere Kosten: Vor allem bei Kleinserien.

- Aussehen: Weniger elegant als Karton für hochwertige Produktpräsentationen.

Abschluss

Die Wahl zwischen Karton- und Wellpappkartons hängt von Ihren Verpackungszielen ab – benötigen Sie lleichte Displayverpackung oder starke schützende Versandbehälter? Jetzt wissen Sie, was eine Wellpappe ist, die Wellpappenkartontypen, und wie Kartons hergestellt werden, Sie sind in der Lage, die beste Entscheidung für Ihre geschäftlichen oder persönlichen Bedürfnisse zu treffen.

Karton eignet sich hervorragend zur Präsentation, aber Wellpappe gewinnt, wenn es um Festigkeit geht, Haltbarkeit, und Vielseitigkeit. Wiegen Sie immer das Produktgewicht, Zerbrechlichkeit, und Vertriebskanal, bevor Sie Ihre Verpackung auswählen.