In folding carton packaging, coatings play a critical role in shaping both visual impact and functional performance. From high-gloss finishes that command shelf attention to matte and soft-touch coatings that convey premium texture, the right surface treatment can significantly influence brand perception, durabilidad, y experiencia del cliente.

En esta guía, we understand how different coating options perform, allowing brands to make informed decisions that balance aesthetics, protección, costo, y sostenibilidad—especially in competitive retail environments.

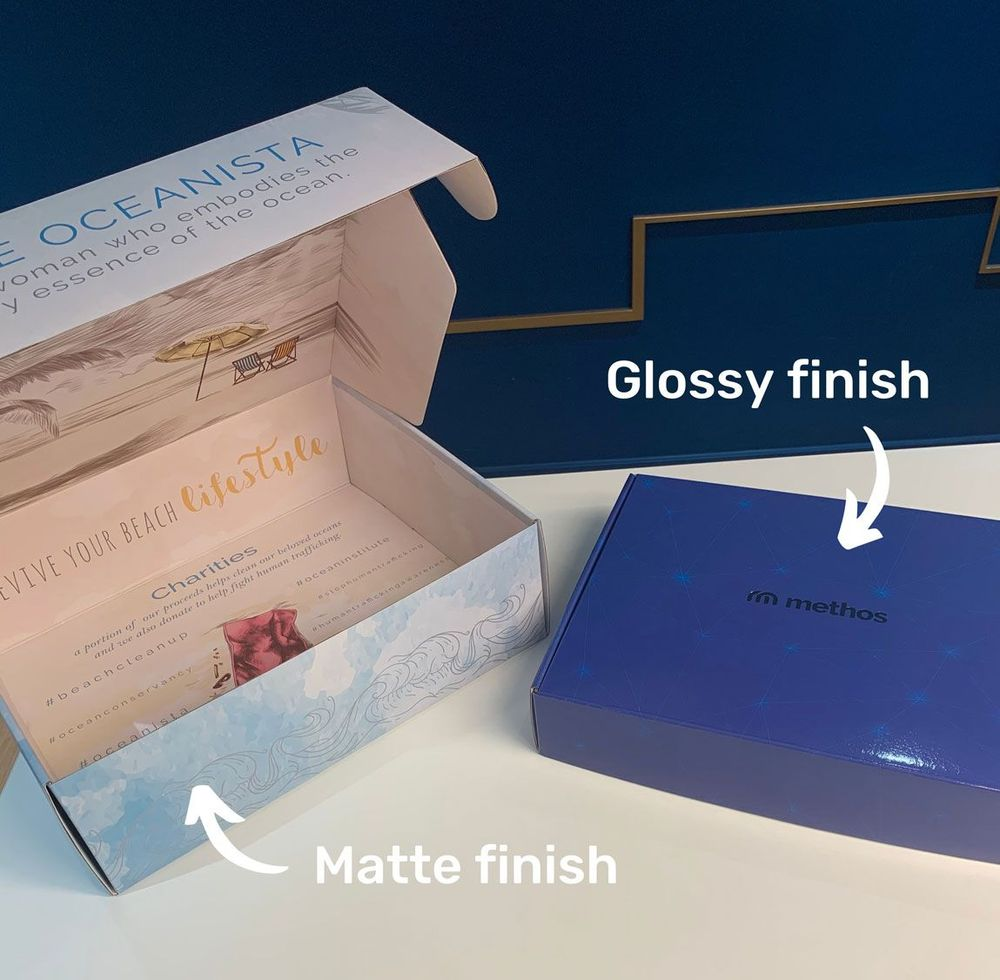

Gloss Coating: Brightness and Appeal

Gloss coating creates a reflective, vibrant surface on folding cartons, significantly boosting color saturation and visual appeal. It uses specialized substrates like high-brightness Solid Bleached Sulfate (SBS) and various coating systems, including gloss UV, to capture light and make products stand out, especially in luxury and retail markets in 2026.

Gloss coating is a key technique for enhancing the visual impact of Cartones plegables. It transforms ordinary packaging into something that catches the eye, making products more attractive on shelves.

This approach is particularly valued by beauty and luxury brands looking to convey premium quality and distinction through their packaging.

Substrates and Coating Systems for High Brightness

The foundation for high-gloss packaging begins with the right board. Folding carton board brightness is usually measured on a scale from 0 a 100. Premium boards, often chosen for luxury brands, achieve brightness levels of 92 a 97.

Materials like Solid Bleached Sulfate (SBS) and White Vellum boards are prime examples, reaching approximately 97 brightness. These provide an excellent base for achieving the desired high-end aesthetic.

To create the glossy finish itself, various coating systems are used. Mineral-pigmented clay top coatings, gloss laminate, and gloss UV coating all contribute to a shiny, reflective surface. Each system offers different levels of gloss and durability.

These coatings intensify colors and add visual depth, which is essential for cosmetic and retail products in 2026. Embalaje de papel Baili offers a range of advanced finishing options, including gloss lamination and spot UV, ensuring brands can achieve precise gloss levels to elevate their packaging presentation.

Matte Coating: Premium Perception

Matte coatings are a strategic choice for brands aiming to convey an image of exclusivity and refined taste. They transform ordinary packaging into a tactile and visual experience that resonates with discerning customers.

Visual & Tactile Characteristics of Matte Finishes

Matte finishes elevate packaging beyond mere protection, engaging both sight and touch to communicate inherent value. Their distinct properties create an immediate impression of quality.

- Achieves a flat, non-reflective appearance with single-digit to low-teens gloss units (GU) at a 60° angle.

- Diffuses incident light, reducing glare and creating a sophisticated ‘satin’ or ‘stealth’ finish.

- Features a slightly rougher, tactile surface, contributing to a luxurious ‘soft-touch’ feel.

- Elevates other design elements, such as embossing and metallic foils, by providing a quiet, understated background.

Technical Foundations of Matte Finishes

Achieving a premium matte appearance requires precise technical specifications and advanced material science. These foundations ensure both aesthetic appeal and long-term durability, a commitment central to Baili Paper Packaging’s offerings.

- Constructed with robust aliphatic thermoplastic polyurethane (TPU) films, típicamente 7-8 mil (180-200 µm) thick, with high-end options at 260 ± 10 µm.

- Features self-healing, often hydrophobic, topcoats for enhanced protection against wear and tear.

- Durability validated through Taber abrasion testing (ASTM D4060) and chemical/UV resistance, offering up to 10 years of protection under normal exposure.

- Includes UV stabilizers and HALS (hindered amine light stabilizers) to prevent yellowing and maintain surface uniformity.

Soft-Touch Coating: Luxury Feel

Soft-touch coatings are a premium finishing technique that transforms ordinary packaging into a memorable sensory interaction. These specialized treatments elevate the tactile quality of folding cartons, creating an immediate perception of luxury and high value.

They are particularly effective for beauty, high-end consumer goods, and other products where a sophisticated feel directly impacts brand positioning and consumer engagement.

| Característica | UV-Curable Systems | Aqueous Systems |

|---|---|---|

| Composition | 100% reactive, solvent-free. Often polyurethane, silicone, or tailored oligomers. | Water-based, translucent. Examples: Roymal, Polytex, Cork Industries. |

| Bio-Content | Can include over 17% renewable bio-content in some formulations. | Typically standard aqueous formulations; bio-content varies by product. |

| Curing/Drying Speed | Rapid, often 250–400 fpm @ 600 W/in Hg, allowing fast production. | Requires air or heat drying, generally slower than UV curing. |

| Application Weight | Around 1.0 lb per 1,000 sq ft for optimal effect. | Similar application weight around 1.0 lb per 1,000 sq ft. |

| Durabilidad (RCA) | Excellent abrasion resistance, RCA >130–300 cycles (35–50 μm film). | Designed for scuff resistance with comparable RCA performance. |

Crafting the Tactile Experience

Soft-touch coatings create a micro-textured, low-gloss surface. This delivers a distinctive velvety or leathery haptic feel to the packaging.

These coatings significantly enhance the perceived luxury and premium quality of folding cartons. This is especially true in beauty and high-end consumer goods sectors.

The finish typically achieves a low gloss of 5–10° at a 60° angle, providing a sophisticated matte aesthetic. Such coatings are suitable for paper, cartón, and selected plastics. They transform ordinary packaging into an engaging sensory experience.

Coating Technologies and Performance

Soft-touch coatings come in different technological forms, each offering specific benefits.Baili Paper Packaging utilizes advanced solutions to ensure exceptional results.

Unlock Brand Impact with Custom Folding Cartons

UV and Protective Coatings

UV coatings are an essential finish for folding cartons, combining strong protection with appealing aesthetics. These advanced coatings make packaging look better and stand up to daily wear and tear.

For beauty and luxury brands, UV finishes are crucial. They help achieve both the necessary durability and the high-end visual impact that customers expect.

Enhancing Packaging with UV Finishes

Exposure to UV light instantly cures these coatings, forming a tough, long-lasting polymer film. This rapid process speeds up production without sacrificing quality or finish integrity.

Many UV formulations meet strict standards for direct food contact and migration. This ensures safety and compliance for food-grade packaging applications where purity is paramount.

Baili Paper Packaging understands how vital these finishes are for luxury and beauty brands. We carefully apply these coatings to enhance both the protection and perceived value of your products.

Technical Specifications and Gluing Dynamics

Típicamente, wet film weights for UV coatings are between 2.0 y 4.0 g/m². This application results in a dry thickness of 3 a 10 micrometers on paperboard, creating a thin yet strong layer.

Baili Paper Packaging applies these technical insights in our manufacturing processes. We ensure that all UV-coated cartons meet stringent standards for both adhesion and overall performance, guaranteeing product integrity.

Selecting the Right Coating for Your Brand

| Coating Type | Primary Benefit (Aesthetic/Sensory) | Key Functional Role | Technical Consideration |

|---|---|---|---|

| High Gloss | Vibrante, reflective appearance; enhances colors. | Offers rub and scratch resistance. | Film weight (2-5 g/m² dry) impacts gloss level and protection. |

| Mate | Non-reflective, sophisticated, muted finish. | Reduces glare; provides surface protection. | Ensures a smooth, uniform, non-sheen appearance. |

| Tacto suave | Luxurious, velvety feel; mejora el valor percibido. | Adds tactile appeal; offers moderate surface protection. | Requires specific formulations for desired haptic quality. |

| Barrier Coatings | Maintains product integrity and clean presentation. | Protects contents from moisture, grasa, and oils. | Water absorption (Cobb 30-80 g/m²) for moisture resistance. |

| Low-Migration Systems | Ensures consumer safety and builds brand trust. | Prevents transfer of substances into the packaged product. | Complies with standards like Nestlé Guidance, Swiss Ordinance. |

Selecting the right coating for folding cartons impacts a brand’s visual identity, protección del producto, and market positioning. Thoughtful consideration of aesthetic appeal, functional requirements, and technical specifications ensures packaging performs optimally.

Baili Paper Packaging supports brands in making these choices by offering a diverse range of coating solutions. We help align your specific needs with advanced finishing options to achieve desired outcomes.

Aligning Coating Properties with Brand Goals

A coating is more than just a protective layer; it is a vital part of your brand’s storytelling and consumer interaction. Different finishes create distinct perceptions and experiences for your product.

- **Brand image impact through gloss levels:** High gloss provides a vibrant, luxurious look, while a matte finish suggests sophistication and subtlety. Satin offers a balanced middle ground. Soft-touch coatings add a tactile, premium sensory experience.

- **Functional protection:** Coatings shield products from damage. They protect against rub marks, scratches, grasa, and water, keeping packaging looking fresh and maintaining product integrity throughout its lifecycle.

- **Aesthetic enhancement for luxury packaging:** For high-end products, coatings elevate materials like SBS boards. Specialty finishes, such as spot UV or textured varnishes, create visual interest and perceived value.

- **Tunable coefficient of friction (COF):** The COF affects how cartons slide during packing and stacking. Controlling COF ensures smooth logistics and a consistent end-user experience when handling the package.

Pensamientos finales

Choosing the right folding carton coating profoundly influences brand perception and product protection. It is a strategic decision balancing aesthetics, durabilidad, and cost-effectiveness.

Smart coating selection ensures your packaging stands out, protege el contenido, and aligns with sustainability goals. This delivers lasting brand impact and value. Baili Paper Packaging provides these tailored solutions.

Contact us from now on to get our solution for paper box packaging and folding cartons!

Preguntas frecuentes

What is the difference between matte and soft-touch coatings?

Matte finishes typically have 10-30 gloss units and use standard aqueous or lamination. Soft-touch provides an ultra-low gloss, often below 10 unidades de brillo, creating a velvety feel with specialized coatings or BOPP film.

Soft-touch offers a distinct ‘velvet’ feel, better scuff resistance, and improved fingerprint resistance, but generally costs more than a standard matte coating.

How durable are UV coatings on folding cartons?

UV coatings are quite durable against rub, scratch, and moderate moisture. They withstand normal retail handling and shelf conditions for years.

These coatings excel for high-gloss, scuff-resistant premium packaging, but they are not suited for extreme abrasion, significant water exposure, or prolonged outdoor UV weathering.

How are fingerprints controlled on luxury folding cartons?

Fingerprints are controlled by selecting coatings like matte, soft-touch, or semi-gloss aqueous finishes, often termed ‘fingerprint-resistant.’

Avoiding high-gloss dark solids, particularly black, helps minimize visible fingerprints. Soft-touch and specific UV matte systems work especially well for luxury packaging.

What is the cost impact of premium coatings on folding cartons?

Upgrading from standard aqueous to premium coatings such as soft-touch, film laminate, or UV/spot UV typically increases carton printing costs by 10–35%.

Standard aqueous coating is the baseline. Soft-touch and laminations usually add 20–30% over aqueous, while full UV systems often cost more due to specialized inks and curing.

Are folding carton coatings eco-friendly?

Sí, folding carton coatings can be eco-friendly, especially with water-based or biopolymer chemistries. They must also ensure the board remains fully recyclable and repulpable, avoiding problematic components.

For luxury cartons, this means using water-based, biodegradable, or plant-based coatings on FSC-certified paperboard with recycled content. Baili Paper Packaging ensures these options are readily available.