Choosing the right printing technique for folding cartons plays a crucial role in packaging quality, brand recognition, and overall cost efficiency. Different printing methods offer varying results in color accuracy, durabilidad, turnaround time, y escalabilidad, making it essential for brands to understand which option best fits their product and market needs.

En esta guía, we’ll compare the most commonly used printing processes, explore their strengths and limitations, and help you determine the most effective solution for achieving high-impact, professional packaging results.

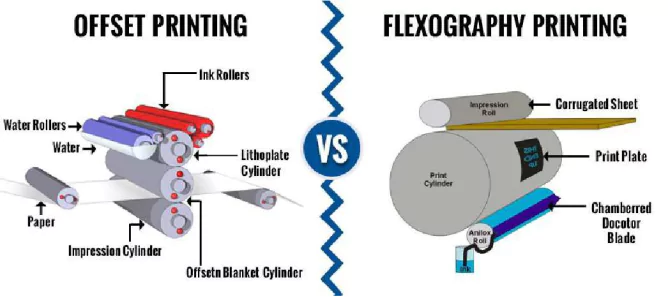

Impresión offset: Pros y contras

Offset printing stands as a primary method for medium to high-volume folding carton production. Brands value it for its excellent image quality and precise color control. This approach delivers cost-effectiveness for static designs but involves significant setup, making it less ideal for very short runs. Modern offset presses manage diverse materials, including heavy board, and offer extensive in-line finishing options for complex packaging.

impresión offset is a cornerstone technology in the production of folding cartons. It offers a powerful blend of quality, velocidad, and efficiency for a wide range of packaging needs. This method delivers consistent results, making it a reliable choice for many global brands.

Understanding its core capabilities and limitations helps in making informed decisions for your packaging projects. Embalaje de papel Baili, for instance, utilizes these insights to guide clients towards the most effective printing solutions.

Benefits and Challenges of Offset Printing

Offset printing provides distinct advantages for packaging, alongside certain operational challenges. Recognizing these aspects helps you choose the most suitable printing method for your specific project requirements.

- It delivers high image fidelity and consistent color. Process and spot colors typically maintain accuracy within ΔE00 ≤ 2.0–3.0 on press, ensuring brand consistency.

- This method proves most cost-effective for medium to high-volume, static runs of folding cartons. Economies of scale become significant with larger orders.

- Offset printing requires substantial setup time and plate production. This makes it less efficient for very short runs or projects with frequent design changes.

- The process uses viscous oil-based inks that dry by oxidation. This demands careful curing for optimal quality and to control ink migration, particularly crucial for food-grade packaging by 2026.

Technical Capabilities and Material Range

Modern offset presses offer remarkable technical performance and versatility in handling various materials. They are engineered to meet demanding specifications for high-quality packaging output.

- It produces sharp graphics, with screen rulings commonly between 85–150 LPI for cartonboard applications. This ensures fine detail and smooth gradients.

- Modern presses expertly handle heavy solid board and corrugated materials. They achieve high production speeds, arriba a 15,000 sheets per hour.

- Press configurations can include up to 19 unidades. This allows for combining multiple colors, revestimiento, and complex in-line finishes in a single pass.

- Offset printing adheres to precise barcode print tolerances. Bar width reduction guidance typically falls around 0.003–0.005 inches, ensuring scannability.

Baili Paper Packaging leverages these advanced offset printing capabilities to deliver high-quality, customized folding cartons. We ensure each project meets stringent aesthetic and functional requirements, from material selection to intricate finishing.

Impresión Digital: Flexibility and Quality

Digital printing delivers exceptional flexibility for short runs, variable data, and rapid design changes in embalaje de cartón plegable.

It achieves quality comparable to offset printing, supporting diverse substrate needs and integrated finishing processes, making it a valuable complement to traditional methods by 2026.

Digital printing has significantly reshaped folding carton production. This method offers important benefits, particularly for adapting to market demands and maintaining high-quality results.

Advantages for Short Runs and Customization

Digital printing brings significant value to folding carton production, especially for efficient short-run jobs and detailed versioning. This approach lets brands produce exactly what they need, without excess.

This technology also supports quick design changes. This is crucial for brands testing new concepts, launching seasonal products, or creating packaging for specific markets. Por 2026, such rapid iterations are becoming a standard expectation.

Data shows that about 55% of converters are seeing more short-run jobs. Digital printing handles this demand effectively, thanks to its quick, data-driven changeovers. Baili Paper Packaging leverages these capabilities to offer flexible order quantities and fast prototyping for both emerging and established brands.

Achieving Offset-Comparable Quality and Versatility

Modern digital carton presses deliver image quality that stands up to traditional offset printing. Sistemas, Por ejemplo, achieve resolutions like 812 × 1219 dpi at 8-bit, ensuring sharp and vibrant visuals.

These presses are also highly versatile in handling materials. They can process various cartonboard thicknesses, arriba a 18 pt / 350 g/m² / 450 µm. They integrate smoothly with finishing processes like UV/aqueous coating and in-line die cutting.

Many B2-format presses, such as the HP Indigo 30000 and Fujifilm JetPress 720S, print large 19.7″ × 27.8″ sheets. This allows for efficient layout of different carton sizes, optimizing material use.

Specific inkjet systems, like the Konica Minolta PKG-1300, print at speeds up to 27 m/min with 300 × 1,200 dpi resolution. They use water-based pigment inks, which are often preferred for packaging due to their environmental profile. This aligns with Baili Paper Packaging’s commitment to materiales ecologicos and sustainable manufacturing practices.

Impresión flexográfica: Cost and Efficiency

Flexographic printing necessitates a notable initial investment, up to US$2 million for high-end presses. Even so, it often yields a 2-5 year payback with consistent utilization.

Its efficiency for long production runs comes from high operating speeds (350-500 m/min), rapid job changes (0.75-1.5 horas), and minimal material waste. Operational costs involve durable plates (US$0.03-0.045 per cm²) and various inks (US$5-30+ per kg). LED-UV curing offers substantial energy savings.

Understanding the financial aspects and operational advantages of flexographic printing is essential for businesses considering this technology for folding cartons. While the initial setup can be substantial, its long-term benefits in large-scale production are clear.

Initial Investment and Return on Investment

The capital expenditure for flexographic printing equipment varies widely. High-end 8-color CI flexo presses, specifically designed for packaging, typically cost between €1.5 to €2.0 million. These machines target demanding production environments and high-quality output.

For smaller operations or specific niche applications, entry-level flexo presses are available for less than US$80,000. Conversely, highly automated platforms, offering advanced features and capabilities, can exceed US$2,000,000.

Well-utilized modern flexographic lines commonly achieve a return on investment within 2 a 5 years. This efficiency comes from the technology’s ability to significantly lower unit costs on longer production runs. This makes flexography a more economical choice compared to digital printing at scale, especially for businesses like Baili Paper Packaging that support diverse client needs for cost-effective, large-volume orders.

Operational Efficiency and Consumable Costs

Flexographic printing systems are recognized for their high operational efficiency. Advanced presses operate at production speeds of 350 a 500 meters per minute. This optimizes throughput for large orders and translates directly into faster delivery times.

Job change waste on an 8-color CI flexo press is minimal, typically around 80–100 meters of substrate. This is a notable improvement over processes like rotogravure, which often incur more significant waste during setup.

Custom Folding Cartons: Elevate Your Brand’s Presence

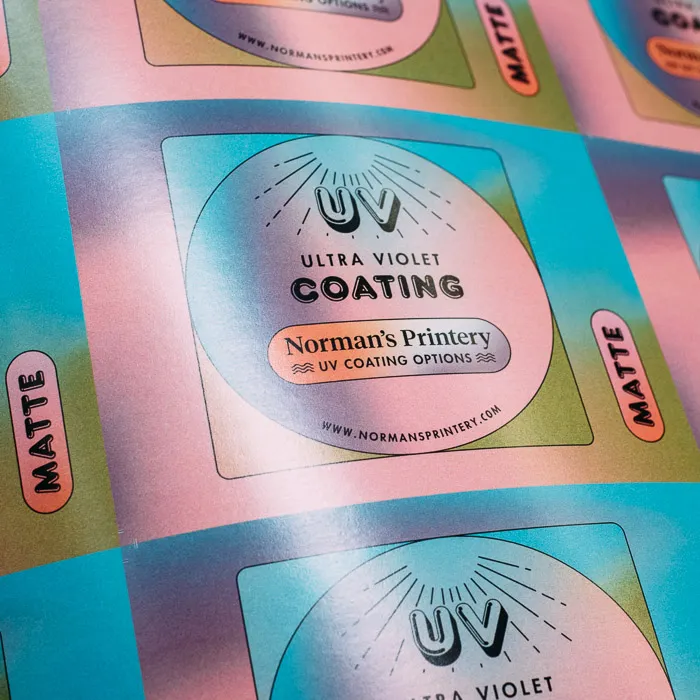

Print Coatings and Finishing Effects

Modern folding cartons rely on a diverse range of coatings and finishing techniques. These applications go beyond aesthetics, offering crucial functional benefits that meet demanding packaging standards for both brand presentation and product integrity.

Such specialized finishes are critical for protecting the printed surface and ensuring cartons perform well on automated packaging lines. Baili Paper Packaging uses these advanced options to create effective and visually appealing solutions.

Enhancing Carton Protection and Visual Impact

Coatings and finishing effects significantly improve both the durability and aesthetic quality of folding cartons. They act as a shield, protecting printed graphics and text from wear and tear during handling and transportation.

These applications extend the lifespan of packaging by preventing rub and scuff marks. They also improve the efficiency of automated packaging processes by offering precise slip resistance for stacking and conveying.

- Coatings and finishes protect print from rub and scuff, extending packaging lifespan.

- They offer slip resistance for efficient stacking and processing on packaging lines.

- Finishes like lamination and embossing add unique visual appeal and tactile elements.

Baili Paper Packaging leverages these advanced coating technologies, including UV and EB-cured options, to meet high gloss and fast-curing requirements. Our expertise ensures that packaging not only looks premium but also performs robustly. We tailor solutions with specific barrier properties and tactile finishes to enhance product value.

Choosing the Right Printing Technique for Your Brand

Selecting the best printing technique for your brand’s folding cartons involves evaluating factors like production volume, required graphic fidelity, color consistency, and budget. Each method—offset, flexographic, and digital—offers distinct advantages in terms of resolution, velocidad, y personalización, making it crucial to align brand objectives with technical capabilities for optimal results.

| Característica | Offset Lithography | Impresión flexográfica | Impresión Digital |

|---|---|---|---|

| Ideal Volume | Medium to Large runs | Large, cost-sensitive FMCG runs | Short runs, prototyping, versioning |

| Graphic Fidelity | High (60s–80s lines/cm, 300 ppp) | Medium (120–150 lpi) | High (variable, comparable to offset) |

| Rentabilidad | Excellent for high volume | Best for large-scale, consistent runs | Optimal for low MOQ, rapid iterations |

| Customization/Versioning | Limited per run | Limited per run | Very High (variable data, personalización) |

Brands aiming for impactful packaging need to understand the nuances of printing techniques. The right choice affects not only visual appeal but also cost-effectiveness and production timelines. Baili Paper Packaging helps brands navigate these complexities, offering expertise across various printing methods. This guide explores how to match your brand’s specific needs with the optimal printing method for folding cartons.

Aligning Brand Vision with Printing Capabilities

Choosing the right printing technique starts with a clear understanding of your brand’s vision and market position. This involves looking beyond aesthetics to core strategic and functional requirements.

- Assess anticipated run length and volume requirements to optimize cost efficiency.

- Consider specific substrate needs, such as solid bleached sulfate (SBS) board or unique textures.

- Determine desired decorative effects, including inline cold foil, specialty coatings, or extended gamut (ECG) options.

- Integrate regulatory and functional content needs, like braille layers or 1:1 scale barcodes.

- Prioritize color consistency and adherence to international standards like ISO 12647 (PSO) across print runs.

Conclusión

Selecting the optimal folding carton printing technique directly impacts your brand’s market presence and budget. Matching your production volume, graphic needs, and desired lead times to the right method prevents costly errors and ensures packaging success.

Making the informed choice translates to significant cost savings, consistent brand messaging, and packaging that performs. Embalaje de papel Baili guides you to the most effective solution, balancing quality with your business goals.

Preguntas frecuentes

What is the difference between offset and digital printing for folding cartons?

Offset lithography is the industry standard for folding carton production runs, while digital printing is suited for short runs, versioning, and personalization.

Offset typically handles paperboard between 250–400 gsm with fine line screens at high speeds. Digital presses, while slower linearly, offer higher native resolution (600–1200 ppp) and significantly faster changeovers, usually taking 5–15 minutes compared to 30–50 minutes for offset.

Is Pantone color matching necessary for folding carton printing?

Pantone is not universally required across all printing, but for folding cartons, it is the industry standard due to the crucial need for precise brand color accuracy and consistency.

Most brand guidelines for folding cartons specify Pantone Matching System (síndrome premenstrual) spot colors over CMYK builds. Major folding carton printers consider PMS the baseline for any color-critical work to maintain brand integrity.

What printing techniques are best for luxury folding carton boxes?

For luxury folding carton boxes, the standard specification involves offset lithographic CMYK printing on premium SBS or C1S/C2S coated board, commonly 300–400 gsm (about 16–24 pt).

Pantone spot colors are typically included for brand-critical hues, along with optional metallic or UV inks, estampado, and embossing as finishing touches. Coated two sides (C2S) board is particularly recommended when a premium printed interior is desired.