When it comes to paper box packaging, businesses often face a crucial decision — should they choose rigid boxes or folding cartons? Both serve as popular packaging types for retail and e-commerce, but they differ greatly in structure, durability, cost, and brand perception.

This guide examines structural and durability differences, cost and production factors, and shipping and storage considerations, helping you match packaging type to budget, handling requirements, and the brand experience you want to deliver.

What is a Folding Paper Box (Carton)?

A folding paper box (carton) is a packaging solution made from paperboard that is die-cut, folded, and glued into a three-dimensional structure; it is widely used in industries such as food, cosmetics, and electronics due to its cost-effectiveness, printability, and versatility.

Definition and Key Features of Folding Paper Boxes

Folding paper boxes, often called folding cartons, are manufactured using paperboard. They are engineered to fold flat, enabling efficient transport and storage.

- Popular in food, cosmetics, and electronics industries for their printability and versatility.

- Reduce shipping volume by up to 80% compared to rigid boxes, lowering logistics costs.

- Can be produced in various shapes and sizes to match product requirements.

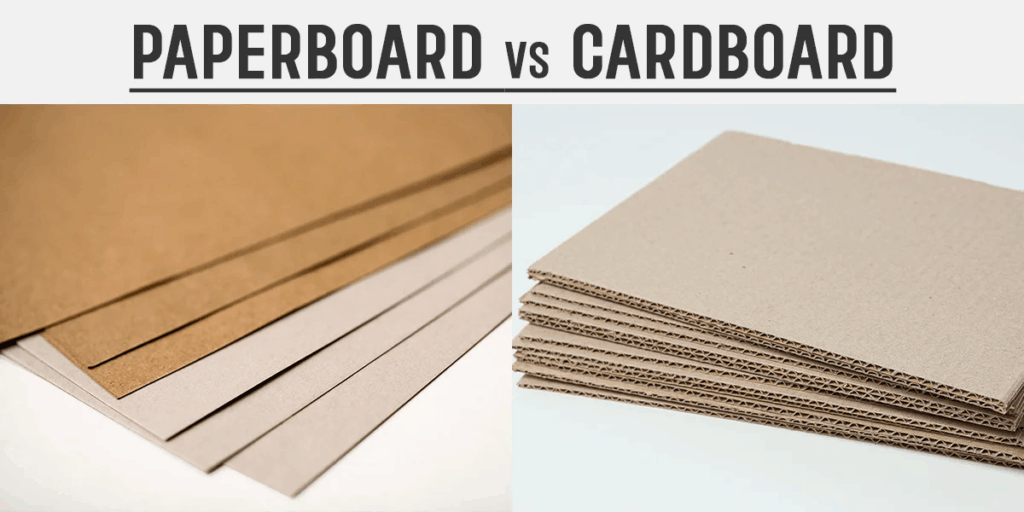

Materials and Production Process

Most folding cartons use paperboard with a thickness between 200 and 500 gsm. This range provides a balance between structural integrity and foldability.

- Material preparation and sheeting

- Printing and die-cutting

- Folding and gluing

- High-speed lines can output up to 400 boxes per minute.

- Standard lead times: 7–21 days based on complexity and order size.

Customization, Finishing Options, and Strength

Folding paper boxes offer numerous ways to enhance product presentation and brand identity. Options range from subtle textures to bold metallic accents.

- Surface finishing: lamination, coating, embossing, debossing, hot foil stamping, window patches.

- Structural capacity: supports 2–5 kg depending on paperboard quality.

- Custom shapes and branded designs to increase retail shelf impact.

Cost Efficiency and Environmental Advantages

When comparing folding paper box vs rigid paper box options, cost and sustainability are major differentiators.

| Aspect | Folding Paper Box | Rigid Paper Box |

|---|---|---|

| Cost | 30–50% less expensive | Higher material and shipping costs |

| Recyclability | Up to 100% recyclable | Often recyclable but with more material use |

| Recycled Content | 60–90% recycled fibers | Typically lower recycled content |

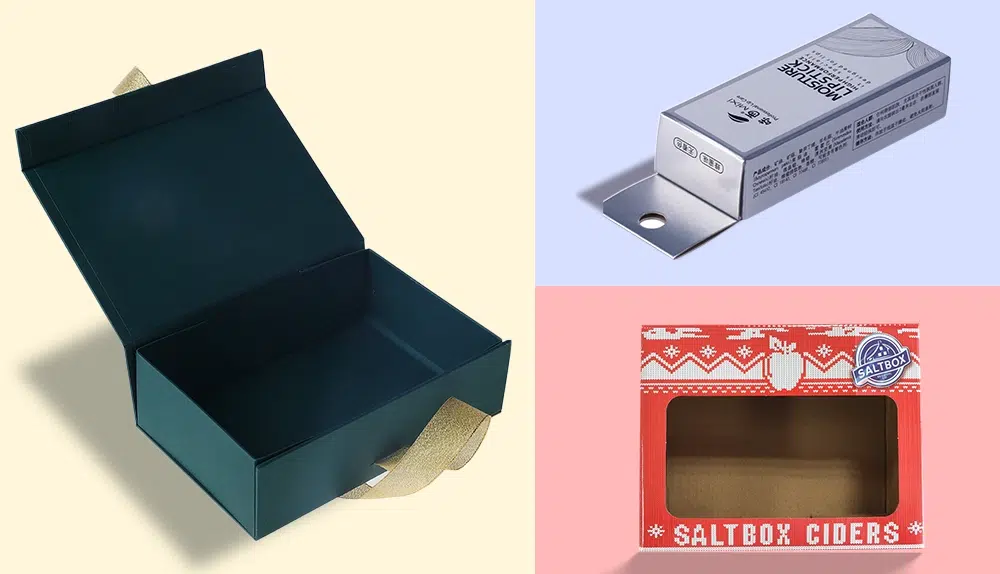

What is a Rigid Paper Box?

A Rigid Paper Box, also known as a Set-Up Box, is a pre-assembled, sturdy packaging made from thick paperboard (2–3 mm chipboard) wrapped in decorative paper. It offers premium product protection and presentation, commonly used for luxury and fragile goods.

Rigid paper boxes deliver premium structural integrity and a distinctive unboxing experience. In our experience, their combination of strength, aesthetics, and ready-to-use form makes them a preferred choice for high-value product packaging.

Definition and Key Features

Rigid paper boxes are constructed to maintain their shape and provide lasting protection. They differ from folding cartons by arriving fully assembled and ready for packing.

- Made from thick chipboard (2–3 mm or 36–120 pt board) for strength and durability.

- Pre-assembled and delivered fully constructed, unlike folding cartons which ship flat.

- Outer surfaces wrapped with decorative materials like art paper, specialty paper, fabric, or leather.

- Common shapes include square, rectangular, circular, triangular, and V-shaped designs.

- Often equipped with lift-off lids, embedded magnets, or telescoping lids for premium user experience.

Benefits and Typical Uses

Rigid boxes balance protection with aesthetic appeal, making them a strategic choice for brand positioning. While they use more space in transit, their perceived value can outweigh added logistics costs.

- Superior protection against crushing and impact, ideal for fragile or high-value items.

- Enhance brand image through premium appearance and customizable finishes.

- Common in electronics, cosmetics, jewelry, board games, and gift packaging.

- Arrive pre-assembled, eliminating on-site assembly costs and saving time.

- Luxury feel increases perceived product value despite higher shipping volume.

Considerations and Misconceptions

Some industries assume rigid boxes are reserved for high-volume orders, but modern production capabilities make them accessible for shorter runs. Planning for their logistical footprint is key.

- Higher shipping and storage costs due to non-collapsible form.

- Longer lead times possible for custom finishes compared to folding cartons.

- Proper dieline engineering prevents structural flaws and ensures box integrity.

- Strategic investment combining product protection with enhanced brand experience.

Structure & Durability Compared

Rigid paper boxes offer superior structure and durability compared to folding paper boxes, which results in a higher perceived value for premium packaging applications among packaging engineers and brand owners.

In our experience working with both rigid and folding paper packaging, structural integrity directly affects performance, branding impact, and customer perception. Below is an in-depth comparison backed by industry data.

Key Structural and Durability Differences

| Specification | Rigid Paper Box | Folding Paper Box |

|---|---|---|

| Material Thickness | 1.2–3 mm chipboard | 0.3–0.7 mm paperboard |

| Compression Strength | Up to 60 kg | Up to 20 kg |

| Stacking Height Without Deformation | Up to 2 meters | Up to 1 meter |

| Typical Lifespan | Years, reusable | Weeks/months, disposable |

| Unit Cost (B2B, USD) | $1.20–$3.50 | $0.10–$0.50 |

Impact on Typical Applications

- Common Applications for rigid: Luxury goods, electronics, cosmetics.

- Common Applications for folding: Food, pharmaceuticals, FMCG.

- Rigid boxes enhance brand perception through superior protection and enhanced unboxing experience.

- Folding boxes offer cost-effective solutions but lower premium value perception.

Packaging engineers in industries targeting high-end consumers tend to prioritize rigidity and finish quality. Folding cartons, while efficient for volume manufacturing, may not deliver the sensory and visual impact expected in luxury segments.

Critical Perspective on Durability and Cost Efficiency

- Increasing thickness or coatings on folding boxes cannot replicate the inherent chipboard rigidity in rigid boxes.

- Folding boxes benefit from flat-pack shipping and low upfront costs, ideal for fast-moving goods.

- Rigid boxes have higher unit costs and longer lead times but deliver lasting protection for premium markets.

- Engineers should weigh total lifecycle costs alongside strategic brand goals, factoring in repeat use potential and customer loyalty gains.

For B2B buyers, selecting between a folding paper box vs rigid paper box is not just a cost choice. It’s a decision about how protection levels, longevity, and presentation align with your brand promise and market positioning.

Elevate Your Brand with Premium Custom Paper Packaging

Unlock sustainable, tailor-made packaging solutions crafted to capture attention and protect your products. Partner with Baili to bring your brand vision to life with expert design, eco-friendly materials, and flawless quality.

Folding paper boxes generally have lower upfront tooling costs and per-unit production costs compared to rigid paper boxes, making them more cost-effective for large-volume packaging, while rigid boxes incur higher initial setup and per-unit expenses due to material and labor intensity.

Cost Comparison Between Folding and Rigid Paper Boxes

| Parameter | Folding Paper Box | Rigid Paper Box |

|---|---|---|

| Upfront Tooling Cost | $300–$1,000 (die-cut mold) | $1,500–$5,000 (custom mold, setup) |

| Per-Unit Production Cost | $0.10–$0.50 (simple designs) | $0.80–$2.50 (luxury finish) |

| Typical MOQ | 1,000–5,000 units | 500–2,000 units |

| Lead Time | 7–14 days | 15–30 days |

| Material Cost | Lower-cost single-layer board | Higher-cost multi-layer wrapped board |

| Labor Intensity | Low labor, mostly automated | High manual labor for assembly/finishing |

| Customization Cost | Lower (print, die-cut) | Higher (embossing, foil stamping, magnets) |

Critical Perspective on Cost and Production Considerations

- Rigid boxes can be 3–5x more expensive per unit than folding boxes, especially for luxury finishes and small orders.

- Higher costs of rigid boxes stem from manual labor and premium materials, not just visual appeal.

- Folding boxes excel in mass-market, cost-sensitive projects needing fast turnaround and high volume output.

- Rigid boxes fit premium or gift packaging where investment is tied to brand image and product protection.

- Brands should carefully assess MOQ and lead times, as rigid boxes often require higher minimum volumes and longer production.

By mapping these factors, decision-makers can align packaging type with budget and brand positioning. Our team regularly guides clients through this analysis to ensure cost-efficiency without sacrificing presentation quality.

Shipping & Storage Compared (Flat-Pack vs. Assembled)

When comparing folding paper box vs rigid paper box logistics, a similar flat-pack versus assembled concept applies. The following sections break down cost, labor, risks, and environmental impact to help packaging engineers and brand managers choose the right model for their products.

Cost and Space Comparison

| Aspect | Flat-Pack | Assembled |

|---|---|---|

| Shipping Cost | Up to 60% lower | Higher due to greater volume |

| Storage Space | Requires 20–50% less space | Bulky, takes more warehouse capacity |

| Cost per Unit | 20–50% cheaper | Higher total landed cost |

In our experience, these savings for flat-pack approaches mirror the efficiencies folding paper boxes have over rigid boxes in bulk eCommerce distribution.

Labor and Handling Considerations

- Flat-pack requires on-site assembly, increasing labor cost and time — complexity affects duration.

- Assembled furniture needs minimal setup, offering immediate usability on delivery.

- Delivery crews: Flat-pack shipments can often be handled by a single driver, while assembled pieces usually require two-person teams and access planning.

For packaging shipment, folding cartons act like flat-pack — lighter, compact, and manageable by fewer handlers compared to pre-formed rigid boxes.

Risk Factors and Environmental Impact

- Properly packed, both types keep damage risk low during transit.

- Flat-pack has higher return risk when assembly is complex or prone to customer error.

- Flat-pack yields lower emissions per item thanks to efficient freight utilization.

- Assembled products create higher freight emissions and are less efficient for long distances.

Similar patterns emerge in folding paper box vs rigid paper box shipping — smaller, flatter packaging improves pallet density.

For packaging decisions, this balance can guide whether to choose folding cartons for scalability or rigid boxes for premium presentation and low-touch fulfillment.

How to Choose the Right Box for Your Brand?

Choosing the right box for your budget and brand requires balancing cost, protection, and presentation: folding paper boxes are generally more cost-effective and customizable for branding, while rigid paper boxes offer superior protection and a premium unboxing experience, but at a higher price point.

In our experience at Baili Paper Packaging, selecting between a folding paper box and a rigid paper box involves a mix of engineering evaluation and brand strategy. The right choice should weigh production costs, logistical efficiency, and the visual impression your packaging creates.

Cost and Production Considerations

| Type | Price per Unit | MOQ | Lead Time |

|---|---|---|---|

| Folding Paper Box | $0.20–$0.80 | 500–1,000 units | 7–15 days |

| Rigid Paper Box | $1.50–$5.00 | 300–500 units ( Higher setup cost) | 15–30 days |

Folding boxes offer significant savings per unit and faster turnaround for high-volume runs. Rigid boxes, while costlier, can support lower MOQs which suits boutique launches, though their extended lead times should be factored in project planning.

Durability, Weight, and Shipping Impact

Folding boxes are optimal for logistics-intensive operations because of their lighter weight and flat-pack shipping advantage. Rigid boxes deliver stronger protection and suit fragile or premium goods, but their bulkier nature raises shipping costs considerably.

Branding and Customization Options

- Folding boxes: Full-color printing, die-cut shapes, and window features for vivid branding

- Rigid boxes: Premium finishes including embossing, foil stamping, magnetic closures, and fabric inlays

- Align customization choices with product positioning to maximize perceived value

In our production workflow, folding boxes are a versatile canvas for creative designs at lower budgets, while rigid boxes elevate tactile appeal in luxury segments.

Critical Perspective: Balancing Costs and Brand Impact

- Consider total cost of ownership, including production, shipping, storage, and brand influence

- Folding boxes: Efficient for high-volume and cost-sensitive sectors like e-commerce and retail

- Rigid boxes: Justify higher costs through enhanced customer experience and product safety

- Shipping cost miscalculations with rigid boxes can inflate budget unexpectedly

We advise packaging decisions that reflect the entire lifecycle expense alongside marketing value. This approach ensures both financial efficiency and brand impact are well balanced.

FAQs

Which is more cost-effective?

In our experience, folding paper boxes are generally more cost-effective due to their lower material usage and simpler assembly. They also occupy less space during shipping, which helps reduce logistics costs.

Rigid boxes, while more premium in appearance and durability, often involve higher material and labor costs, making them less budget-friendly for high-volume, low-margin products.

Can rigid boxes be flat-packed?

Most rigid boxes cannot be flat-packed due to their fixed structure made from thick paperboard. This means they take up more storage and shipping space.

There are collapsible rigid box designs available, but they require custom engineering and often come at a higher unit price compared to standard rigid formats.

What are common rigid box types?

- Lift-off lid boxes (two-piece)

- Magnetic closure boxes

- Drawer or slide-out boxes

- Book-style or clamshell boxes

Each type offers different aesthetic and functional benefits, often chosen based on product positioning and unboxing experience goals.

Which is better for eCommerce shipping?

Folding paper boxes are a strong choice for eCommerce when paired with protective inserts or outer cartons, offering lower weight and shipping costs.

Rigid boxes provide superior protection and a premium presentation but increase both packaging weight and shipping volume, which can mean higher freight fees.

What’s the MOQ difference?

MOQ, or minimum order quantity, for folding paper boxes can be as low as 500 units with our flexible production setup. This is suitable for startups and limited runs.

Rigid boxes typically have higher MOQs, often starting at around 1,000 units, due to labor-intensive processes and setup costs.

Both rigid boxes and folding carton packaging bring their own strengths to the table. Rigid boxes emphasize luxury, protection, and brand prestige, while folding cartons deliver flexibility, sustainability, and cost efficiency.

Your choice ultimately depends on your brand story and customer expectations. Whether you need a collapsible rigid box for premium appeal or eco-friendly folding cartons for mass retail, the right partner can make all the difference.

Work with experienced packaging experts at bailipaperpackaging.com to design packaging that not only protects your product—but also elevates your brand presence and customer experience.