L'emballage en carton peut sembler simple au consommateur final : un emballage soigné, boîte colorée qui protège et affiche le produit. Mais dans les coulisses, le processus de production d'emballages en carton est plein de complexités. Des incohérences des matières premières aux exigences de durabilité, les fabricants d’emballages sont confrontés à un large éventail d’obstacles qui peuvent ralentir la production, augmenter les coûts, et même avoir un impact sur la réputation de la marque.

Dans cet article, nous allons démonter le haut 6 défis dans la production d'emballages en carton, expliquer pourquoi ils se produisent, explorer leur impact sur les opérations, et proposer des solutions pratiques que les entreprises peuvent mettre en œuvre. Que vous exploriez des boîtes en carton pliantes personnalisées ou que vous expérimentiez de nouvelles Styles de cartons personnalisés, comprendre ces défis vous aidera à prendre des décisions plus judicieuses et à travailler plus efficacement avec fabricants de cartons pliants.

| Défi | Problème principal | Impact |

| Qualité des matériaux incohérente | Variations dans la résistance et la finition du carton | Cartons faibles, ressources gaspillées |

| Conception structurelle & Problèmes de découpe | Erreurs dans les lignes de découpe et la précision de coupe | Mauvais ajustement, produit endommagé |

| Impression & Cohérence des couleurs | Inadéquation et désalignement des couleurs | Incohérence de la marque |

| Collage & Complications de pliage | Défaillances d'adhésif et de plis | Finitions bâclées, retards |

| Délais d'exécution courts & Commandes urgentes | Des délais serrés | Augmentation des erreurs, des coûts plus élevés |

| Durabilité & Gestion des déchets | Recyclage et éco-réglementation | Inefficacité de la production, coûts de matériaux plus élevés |

Qualité des matériaux incohérente

Pourquoi cela arrive

- Variation du fournisseur

Tous les fournisseurs de carton ne maintiennent pas la même résistance des fibres, qualité du revêtement, ou épaisseur.

- Sensibilité environnementale

Le carton réagit à l'humidité et à la température, conduisant à une déformation ou à une fragilité.

- Risques de réduction des coûts

Certains fabricants peuvent sélectionner des cartes moins chères pour réduire les dépenses, sacrifier la durabilité.

Impact sur la production

- Faiblesse structurelle

Les matériaux fragiles s'effondrent facilement, affectant la sécurité des transports.

- Mauvaise imprimabilité

Les surfaces de mauvaise qualité entraînent des graphiques ternes et des problèmes d’absorption des couleurs.

- Un gaspillage élevé

Les lignes de production peuvent rejeter les feuilles défectueuses, faire grimper les coûts.

Solutions

- Collaborez avec des fabricants de boîtes pliantes qui disposent de systèmes de contrôle qualité rigoureux.

- Établir un protocole de test standard pour tous les lots de carton entrants.

- Passez à des boîtes en carton pliantes personnalisées haut de gamme pour les produits qui nécessitent une protection plus forte et un meilleur attrait en rayon.

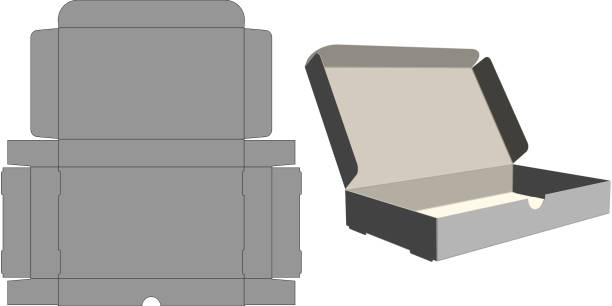

Problèmes de conception structurelle et de découpe

Pourquoi cela arrive

- Styles de cartons complexes

Les styles de cartons personnalisés innovants nécessitent souvent des découpes complexes qui laissent peu de place à l'erreur..

- Machines obsolètes

Les machines de découpe plus anciennes ont du mal à offrir une précision à grande vitesse.

- Mauvaise communication lors de la conception

Le manque de coordination entre les graphistes et les équipes de production crée des décalages dans les lignes de découpe.

Impact sur la production

- Difficultés de montage: Les coupes mal alignées empêchent le pliage et le collage en douceur.

- Protection affaiblie: Les cartons mal coupés peuvent se déchirer ou s'effondrer lors de la manipulation.

- Ressources gaspillées: Des tôles mal découpées entraînent des pertes de matériaux élevées.

Solutions

- Utiliser Outils de CAO et de simulation 3D pour tester la résistance structurelle avant la production en série.

- Planifiez un étalonnage et une maintenance réguliers de la machine pour garantir la précision.

- Favoriser une collaboration plus étroite entre les équipes de conception et de production pour aligner les attentes.

Impression et cohérence des couleurs

\

Pourquoi cela arrive

- Variabilité de l'encre: Différents fournisseurs ou lots d'encre produisent des nuances incohérentes.

- Méthodes d'impression: Compenser, flexographie, et l'impression numérique se comportent chacune différemment sur le carton.

- Influence environnementale: La température et l'humidité peuvent affecter les temps de séchage de l'encre.

Impact sur la production

- Dommages à la marque: Les couleurs incohérentes de la marque érodent la confiance et la reconnaissance des clients.

- Augmentation des réimpressions: Une sortie couleur incorrecte nécessite souvent des reprises coûteuses.

- Retards: Des contrôles de qualité supplémentaires ralentissent les délais d'exécution.

Solutions

- Standardisez avec les systèmes de correspondance des couleurs Pantone ou CMJN pour garantir l'exactitude.

- Exécutez des tests d'impression sur le matériau du carton réel avant des tirages complets.

- Maintenir des partenariats à long terme avec des fournisseurs d'encre de confiance pour plus de cohérence.

Complications du collage et du pliage

Pourquoi cela arrive

- Inadéquation des adhésifs: Utiliser la mauvaise colle pour un type de carton particulier.

- Notation incorrecte: Un mauvais rainage empêche des plis nets.

- Problèmes de vitesse élevée: Sur les lignes rapides, la colle n'a pas assez de temps pour durcir.

Impact sur la production

- Échecs d'emballage: Les boîtes s'ouvrent pendant l'expédition ou la manipulation en magasin.

- Inefficacités de production: Les ouvriers passent du temps à retravailler les cartons défectueux.

- Risques pour la réputation de la marque: Un emballage bâclé nuit à la valeur du produit.

Solutions

- Investissez dans des systèmes de collage automatisés pour une application précise.

- Former les opérateurs à ajuster les plieuses pour chaque style de carton.

- Testez les adhésifs spécifiquement pour le type de panneau et le poids du produit.

Délais d’exécution courts et commandes urgentes

Pourquoi cela arrive

- Demande de commerce électronique: Des lancements de produits plus rapides nécessitent une préparation à l'emballage.

- Pointes saisonnières: Les promotions et les jours fériés créent une augmentation soudaine des commandes.

- Changements de dernière minute: Les clients peuvent mettre à jour la marque ou les spécifications du carton à la fin du cycle.

Impact sur la production

- Exécutions sujettes aux erreurs: Accélérer la production augmente le risque d’erreurs.

- Stress des travailleurs: Les heures supplémentaires et les conditions précipitées peuvent causer de la fatigue.

- Des coûts plus élevés: Les commandes urgentes exigent une expédition accélérée et une allocation de ressources plus élevée.

Solutions

- Intégrez une capacité tampon dans les calendriers de production pour gérer les tâches urgentes.

- Mettre en œuvre des pratiques de production Lean pour maximiser l’efficacité.

- Encouragez les clients à planifier à l’avance tout en offrant des tarifs majorés pour les projets urgents.

Durabilité et gestion des déchets

Pourquoi cela arrive

- Des exigences écologiques: Des réglementations croissantes poussent à des emballages recyclables et biodégradables.

- Inefficacités matérielles: De mauvaises dispositions de découpe génèrent un excès de déchets.

- Les attentes des consommateurs: Les marques doivent démontrer leur engagement en faveur du développement durable.

Impact sur la production

- Coûts de matériaux plus élevés: Les substrats durables sont souvent plus chers.

- Ajustements de production: Les nouveaux éco-matériaux peuvent nécessiter un recalibrage des machines.

- Risques de réputation: Les entreprises qui ne respectent pas les normes vertes risquent de perdre des clients.

Solutions

- Optimisez les styles de cartons personnalisés pour une efficacité matérielle et un minimum de déchets.

- Collaborez avec des fournisseurs proposant des planches certifiées FSC ou recyclées.

- Investir dans systèmes de recyclage en boucle fermée réutiliser les chutes et les erreurs d'impression.

Conclusion

L'emballage carton continue d'être un choix privilégié dans tous les secteurs grâce à sa polyvalence., imprimable, et potentiel de développement de la marque. Encore, c'est loin d'être un processus simple : qualité des matériaux incohérente, défauts de structure et de découpe, défis d'impression, problèmes de collage, délais précipités, et durabilité les exigences posent toutes des obstacles importants.

La bonne nouvelle est qu'avec une planification intelligente, de meilleures relations avec les fournisseurs, et des investissements réfléchis dans la technologie, ces défis peuvent être surmontés. En travaillant avec des fabricants de boîtes pliantes expérimentés, choisir des boîtes en carton pliantes personnalisées et durables, et explorer des styles de cartons personnalisés innovants, les entreprises peuvent équilibrer leurs performances, durabilité, et esthétique : garantir que leur emballage protège le produit tout en se distinguant en rayon.

FAQ

Quels sont les inconvénients d'un produit emballé dans un carton?

Bien que les cartons soient hautement adaptables, ils peuvent être vulnérables à l'humidité et à l'écrasement, sujet à des défauts structurels s’il est mal fait, et coûteux à produire de manière durable. Les variations d'impression et les complications de pliage peuvent également nuire à l'image de marque..

Comment choisir des fabricants de boîtes pliantes fiables?

Recherchez des fabricants certifiés (FSC, OIN), tel que Bailipaperpack—- une expérience de travail avec des marques internationales, et la possibilité de fournir des échantillons ou des prototypes. La communication et la réactivité sont également essentielles.

Quand devrais-je envisager des boîtes en carton pliantes personnalisées?

Si votre produit a besoin d'une protection plus forte, marque haut de gamme, ou des formes uniques pour se démarquer sur les étagères, investir dans des boîtes en carton pliantes personnalisées est une décision judicieuse. Ils permettent une flexibilité de taille, conception, et options de finition.