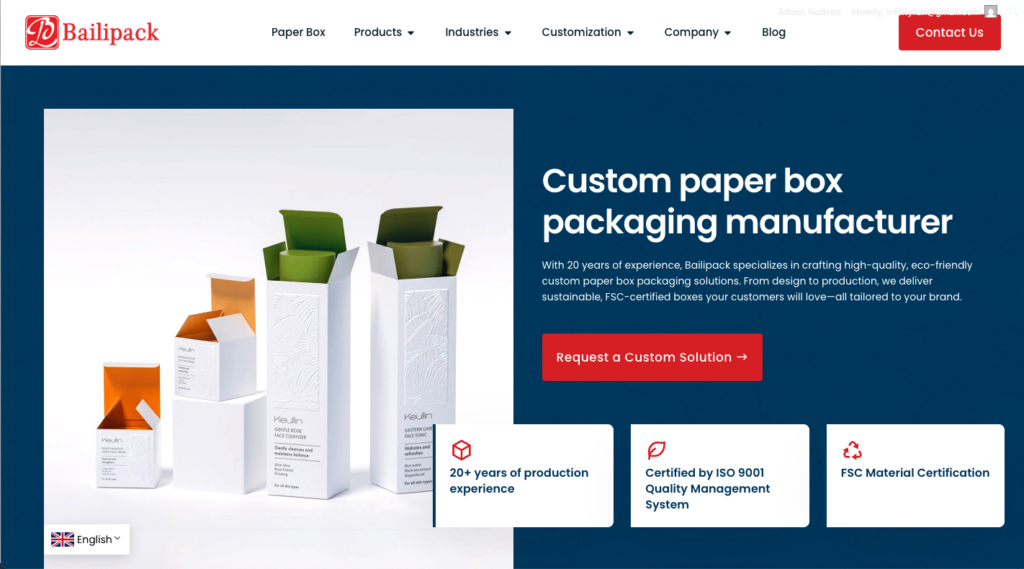

Many brands struggle to source custom paper box packaging that delivers both refined visual precision and dependable structural performance. Inconsistent materials, loose print tolerances, and unreliable production timelines often result in design compromises or product damage that impacts brand value.

で 百里紙パック, we address these challenges through an ISO 9001–certified production workflow, rigorously validating material specifications such as 600 µm caliper paperboard and maintaining a strict ±1/8 inch print registration tolerance. Combined with efficient 7–12 day lead times, we help brands achieve packaging that looks right, performs reliably, and arrives on schedule.

What Makes Baili a Trusted Custom Paper Box Manufacturer

Baili’s Deep Experience and Integrated Service Model

We offer a one-stop OEM/ODM service. This integrated approach covers every step: from initial research and development to design, 印刷, and final production. This complete solution simplifies the process for clients, ensuring consistency and seamless execution.

Advanced Production and Quality Assurance Systems

Our advanced production facilities are central to Baili’s reliability. Our 7,350 m² plant houses 119 従業員, collectively producing around 180 million pieces of packaging annually. This scale allows us to handle high-volume orders efficiently.

Efficiency is key. We provide fast lead times, with samples ready in 1–3 days. Mass production typically takes 7–12 days. This speed helps clients meet tight market schedules.

Our flexible Minimum Order Quantities (MOQs), ranging from 500 to over 500,000 単位, accommodate diverse business sizes and project scales. An intelligent quality management system ensures consistent product standards across all batches.

Baili also prioritizes sustainable practices by using FSC-certified paper materials. This commitment reflects our dedication to both product excellence and environmental responsibility, aligning with eco-conscious brand initiatives.

Material Options for Custom Paper Boxes (SBS, クラフト, Specialty Boards)

Baili offers Solid Bleached Sulfate (SBS) for vivid print quality, Kraft paperboard for strength and sustainability, and Specialty boards like rigid grayboard or corrugated for luxury and protective packaging.

These options meet diverse brand needs from high-end cosmetics to durable e-commerce solutions, ensuring optimal product presentation and protection.

Choosing the right paperboard material is vital for custom paper box packaging. It directly influences product durability, print quality, and overall brand perception.

Baili provides a comprehensive range of material options, each tailored to specific product needs and aesthetic goals.

Key Paperboard Choices

- **固体漂白硫酸塩 (SBS):** This material offers a smooth, bleached surface ideal for high-quality, vivid printing. It suits cosmetics and premium electronics packaging well.

- **Kraft Paperboard:** In its natural brown form, kraft provides high strength, tear resistance, and recyclability. Brands often choose it for a sustainable aesthetic.

- **Specialty Boards:** This category includes rigid grayboard, used for luxury rigid box structures, and microflute corrugated options, which offer added protection and print flexibility.

Material Specifications and Performance

- **SBS Paperboard:** Available as C1S (coated one side) or C2S (coated two sides), typically ranging from 250–350 gsm. C2S versions are frequently laminated for enhanced scuff and moisture resistance in retail cartons.

- **Kraft Paperboard:** Brown kraft 折り畳みカートン commonly use 250–300 gsm. Unbleached, uncoated kraft linerboard excels in maximum strength and recyclability for transit packaging. Solid Unbleached Sulfate (SUS) offers superior stiffness and tear resistance per basis weight.

- **Specialty Boards:** Rigid grayboard uses compressed recycled paperboard in various thicknesses for luxury box bases. F-flute corrugated, around 0.8–1.0 mm thick, balances rigidity with high print quality for smaller retail boxes.

Structural Designs Available at Baili (Folds, Closures, インサート)

Baili offers a variety of structural packaging designs, including versatile folding cartons and robust rigid boxes, complemented by specialized plastic folding options. These structures integrate various closure systems and custom inserts.

Each design is engineered for specific product requirements and efficient, high-quality production.

| Packaging Type | Main Material | Thickness Range | Key Strength / Capacity | Typical MOQ |

|---|---|---|---|---|

| 紙器 | 板紙 | 0.3–0.7 mm | 2–5 kg product load; ≤20 kg compression | 500–2,000 units |

| リジッドボックス | Heavier Chipboard | 1.2–3.0 mm | Up to 60 kg compression | 1,000–5,000 units |

| Corrugated Options | E-flute, B-flute | 0.5–3.0 mm | Ideal for transit and e-commerce | Varies by project |

| Plastic Folding Boxes | ペット, PVC, PP | Variable (薄い) | Up to 200,000 units daily capacity | から 500 単位 |

Baili provides a comprehensive range of structural packaging designs tailored to product protection and aesthetic presentation. We ensure each solution meets both functional requirements and brand vision.

Our expertise spans various materials and construction methods, offering versatility for many industries and product types.

Core Packaging Architectures and Closure Systems

Baili’s portfolio includes 折り畳みカートン, rigid set-up boxes, そして plastic folding boxes. A dedicated sister entity handles plastic options using materials like ペット, PVC, and PP.

Folding cartons are made from paperboard. They offer flexible, one-piece designs often chosen for high-volume retail items.

Rigid boxes use heavier chipboard. They provide enhanced durability and a premium feel, frequently selected for luxury goods.

We offer various closure systems to secure your products. These include lift-off lids, telescoping lids, and embedded magnetic closures. Simple tuck and fold mechanisms are also available.

Custom inserts and internal fitments provide additional product protection. We use materials like duplex board, corrugated flutes, or specialty papers. Rigid boxes can feature fabric or paper inlays for an elevated feel.

Elevate Your Brand with Premium Custom Eco-Packaging

印刷 & Finishing Techniques Baili Offers

| 技術 | カテゴリ | Key Feature / 利点 |

|---|---|---|

| オフセット印刷 | 印刷 | Vibrant, high-fidelity color on white cardboard substrates |

| UV Printing | 印刷 | Enhanced durability, chemical resistance, instant ink curing |

| Silk Screen Printing | 印刷 | Thicker ink layers, unique tactile finishes |

| ラミネート加工 | 仕上げ | Adds water and tear resistance using heat-activated plastic film |

| 箔押し | 仕上げ | Applies metallic, pigmented, or holographic effects with high reflectivity |

| エンボス加工 | 仕上げ | Creates raised relief designs for impactful logos and brand marks |

| UVコーティング / ニスをかける | 仕上げ | Provides scratch/scuff resistance, controls sheen, and achieves luxury aesthetics |

Baili employs advanced printing and finishing techniques to ensure your custom paper box packaging stands out. These methods not only boost visual appeal but also add crucial protection to your products.

Baili’s Core Printing Methods

Baili uses a variety of core printing methods to achieve vibrant, precise, and durable graphics on your custom paper boxes. Each technique offers distinct advantages tailored to specific design and functional requirements.

- Baili offers offset printing for vibrant, high-fidelity color graphics on white cardboard substrates.

- We provide UV printing for enhanced durability, chemical resistance, and special effects, instantly curing inks with UV light.

- Baili utilizes silk screen printing for thicker ink layers and unique tactile finishes on packaging.

Specialized Finishing for Enhanced Appeal

Beyond printing, Baili offers specialized finishing applications that elevate the aesthetic appeal and tactile experience of your packaging. These finishes provide added protection and a premium feel.

- Baili applies lamination, using heat-activated plastic film, to add water and tear resistance for frequently handled packaging.

- We offer UV coating in gloss, satin, or matte to provide scratch and scuff resistance, cured by UV light.

- Baili provides foil stamping, using heat and pressure with metal dies, for metallic, pigmented, or holographic effects with high reflectivity.

- We create raised relief designs with embossing, often combined with foil or spot UV for impactful logos and brand marks.

- Baili uses varnishing (光沢, マット, silk/satin, スポットUV) to control sheen, protect ink, and achieve luxury aesthetics.

- We integrate glitter for eye-catching sparkle and visual appeal on select areas of the packaging.

カスタマイズ機能: サイズ, Shape, Branding, and More

Baili provides custom paper box packaging solutions, allowing precise adjustments in size, 形, and structural design. These adjustments are guided by current industry performance standards.

We integrate detailed branding elements with technical printing specifications. This ensures impactful and functional packaging for 2026.

Baili offers extensive customization for paper box packaging. We ensure your brand vision aligns with robust engineering standards for size, 形, and detailed branding.

Engineering Tailored Dimensions and Structures

Baili engineers packaging to meet exact technical requirements and industry standards. Our approach ensures every box performs reliably, from stacking to handling.

- We customize fiberboard grade, flute combination, and box style. This is based on performance needs, including stacking and handling, as defined by ASTM D5639/D5639M.

- Our team fabricates boxes to consistent dimensions and tolerances. We follow ASTM D5118/D5118M practices for various styles like slotted, telescope, and folder-type designs.

- We integrate specific features, such as hand holes or die-cut grips, carefully. We adhere to ASTM D6804 design guides to maintain structural integrity.

- We ensure all custom shipping cartons meet retailer specifications. This includes maximum external dimensions of 24 in × 24 in × 24 で (61 cm × 61 cm × 61 cm) and a minimum burst strength of 200 psi.

Precision in Branding and Print Specifications

Achieving impactful branding requires precise technical execution. Baili combines visual design with strict printing standards to ensure your brand stands out and functions correctly.

Eco-Friendly and Sustainable Packaging Options

で 2026, eco-friendly paper packaging focuses on fiber-based materials like kraft and recycled boards, substantiated by certifications such as FSC and PEFC. Key strategies include using water-based inks, avoiding plastic laminates, and employing right-sizing designs to enhance recyclability and reduce environmental footprint.

Brands increasingly seek packaging solutions that align with environmental values. This means moving towards materials and designs that minimize ecological impact throughout their lifecycle.

For custom paper box packaging, sustainability involves careful choices from raw material sourcing to end-of-life considerations. These choices impact recyclability, compostability, and overall resource consumption.

Sustainable Materials and Certifications

Choosing the right materials is the first step toward eco-friendly packaging. We prioritize fiber-based substrates for custom paper boxes, ensuring they come from responsible sources and support circular economy principles.

- We use fiber-based materials like natural kraft paper, which provides inherent strength and a rustic aesthetic. Recycled paperboard, containing 30-50% post-consumer recycled (PCR) fiber, offers a robust option for reducing virgin material use. FSC-certified SBS paperboard is also available, guaranteeing responsible forest management.

- For specific coatings and molded pulp systems, we look for compostability standards. These include EN 13432 (ヨーロッパ), ASTM D6400 (私たち), and TÜV OK Compost certifications. These ensure packaging breaks down naturally without harming the environment.

Baili Paper Packaging integrates these certified materials into custom solutions, helping brands meet their sustainability goals.

私たちがサービスを提供する業界: Beauty, エレクトロニクス, 食べ物, Luxury Goods

Baili provides specialized custom paper box packaging for beauty, エレクトロニクス, 食べ物, and luxury brands. This includes selecting appropriate materials like 350-400 GSM folding cartons or 1000-1800 GSM rigid boxes.

We ensure compliance with standards such as ASTM, TAPPI, and food-grade regulations. We also offer diverse finishing options to meet each sector’s unique demands for protection, プレゼンテーション, そして持続可能性.

Tailored Packaging Solutions for Diverse Industries

Baili understands that each industry presents unique packaging requirements. We design and manufacture custom paper boxes to meet these specific needs, from aesthetic appeal to strict regulatory compliance.

For beauty and luxury goods, Baili offers premium finishes and robust structures. This ranges from 350-400 GSM folding cartons for cosmetics to 1000-1800 GSM rigid boxes for high-end perfumes and watches.

エレクトロニクス packaging from Baili focuses on essential product protection and appealing retail presentation. We use 200-400 GSM carton board for secondary packaging and up to 1200 GSM corrugated for secure shipping.

食品包装 prioritizes safety and hygiene above all. Baili uses 10-28 pt board materials, such as Kraft and E-flute corrugated, designing solutions that fully meet product integrity needs.

Baili’s adaptable production supports low Minimum Order Quantities (MOQs) for emerging brands. We also handle large-scale manufacturing for established enterprises across these diverse markets, integrating advanced printing and finishing.

Baili’s Quality Control & Production Process

Integrated Quality Management System

Baili operates from a 7,350 m² facility, which houses a fully integrated folding-carton workflow. This setup promotes consistent quality across all production cycles.

Adherence to ISO 9001 quality management principles guides every production and quality control activity. This framework ensures a systematic approach to maintaining standards.

Baili uses automated, precision equipment to minimize dimensional variance. This technology helps ensure consistent product output, crucial for custom packaging.

Precision Production Stages and Quality Checkpoints

Material selection is rigorous, starting with verification of paperboard grades. This includes options like 120–300 gsm kraft and 250–400 gsm duplex, ensuring the right foundation for custom paper box packaging.

Baili ensures color accuracy through pre-press proofing and machine calibration. This guarantees CMYK and Pantone spot colors match brand specifications perfectly.

Key quality checkpoints are built into the workflow. These include structural strength tests, print quality verification, and pre-production sample approvals. Each step confirms packaging integrity and visual appeal.

よくある質問

What materials can I choose for custom paper boxes?

Baili offers a variety of materials for custom paper boxes. These include paperboard like SBS/C1S/C2S and CCNB/duplex, which often have high recycled content.

Other options are brown or white kraft paperboard, grayboard for rigid boxes, and corrugated board in various flutes (E-flute, F-flute, and thicker options).

These materials can be combined with coatings/laminations such as gloss/matte art paper or metallic film, specified by basis weight (gsm) and board thickness (mm or inch).

What is the minimum order quantity (MOQ) at Baili?

Baili Paper Packaging typically sets its minimum order quantity (MOQ) for custom paper boxes between 500–1,000 units.

Brands can often start custom runs for as few as 500 boxes for specific designs.

Does Baili support sustainable packaging options?

Baili provides robust sustainable packaging solutions. We use recycled materials, FSC-certified sources, and eco-friendly manufacturing practices.

Baili adheres to global environmental standards like ISO 9001 and ISO 14001. Our sustainable portfolio includes recycled paperboard, unbleached kraft paper for compostability, and biodegradable coatings.

FSC certification confirms responsible forest sourcing, while ISO 14001 ensures effective environmental management systems. Switching to Baili’s recycled paperboard offers energy and water savings, supports closed-loop recycling, and reduces carbon emissions.

By 2026, 61.0% of raw material in the paperboard packaging market is projected to be recycled waste paper, a goal Baili actively pursues.

Can I order prototypes before mass production?

はい, producing physical prototypes is standard practice for custom paper box packaging. Baili offers 1–3 rounds of prototypes.

These typically include unprinted and then printed/press-proof samples before mass production. Prototyping usually takes 1–3 weeks, with the first full production run adding 7–15 days after final sample approval.

What industries does Baili serve?

Baili serves a diverse range of industries, 食べ物も含めて & 飲み物, cosmetics/beauty, エレクトロニクス, retail/consumer goods, 医薬品 & 健康管理, and toys.

We design plastic and paper boxes, blisters, and cartons as cross-industry packaging solutions, serving over 13 industries with custom packaging expertise.