Packaging designers, eコマース販売者, and manufacturers often face a trade-off when choosing between cardboard boxes and paper boxes — balancing durability, 料金, and brand presentation without compromising sustainability. The wrong choice can lead to product damage, higher expenses, or misaligned customer expectations.

This guide compares material strength and durability, cost and production efficiency, and sustainability factors, helping industry professionals select the right option that protects products, controls budgets, and supports brand image. Let‘s dive in!

What is a Cardboard Box?

A cardboard box is a sturdy packaging material made from multiple layers of compressed paper fibers, usually with a corrugated or solid structure, providing greater strength and durability than standard paper. These boxes protect and transport various products and are widely used in shipping, ストレージ, and e-commerce.

Cardboard boxes play a critical role in the packaging industry, especially for businesses focused on safe transport and storage of goods. They balance durability, cost-efficiency, そして持続可能性, making them a preferred choice over single-layer paper boxes.

Definition and Composition

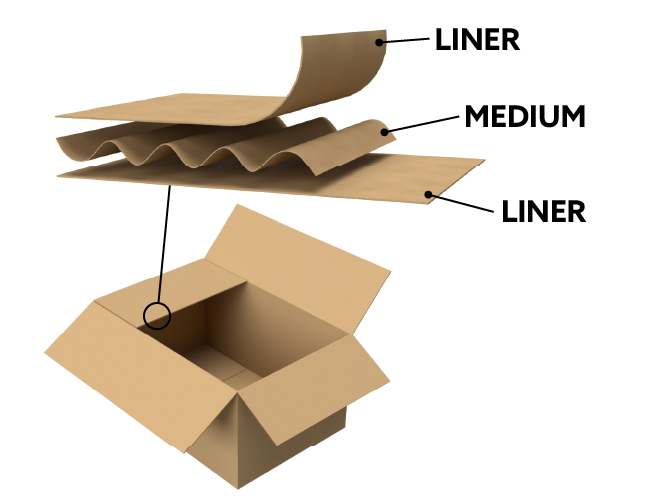

Cardboard is made from multiple layers of compressed paper pulp bonded together with adhesives. The most common type, corrugated cardboard, consists of three layers: two outer liners and a fluted inner medium.

This layered design creates small air pockets that boost rigidity without adding excessive weight. 私たちの経験では, this structure offers significant advantages in handling and stacking during transit.

- Multiple layers of compressed paper pulp for strength

- Corrugated design with fluted medium for impact resistance

- Air pockets reduce weight while improving rigidity

- Stronger and more durable than single-layer paperboard

| Specification | 段ボール箱 | 紙箱 |

|---|---|---|

| 耐荷重 | 60 lbs+ | 30 lbs |

| Thickness | Multi-layer design | Single-layer |

| Cost per Unit | $0.50–$2.00 | Lower upfront cost |

| Recycled Content | 70% recycled, fully recyclable | Recyclable with lower recycled content |

| Damage Reduction in Transit | 90% less damage | Higher risk of damage |

| 耐湿性 | Not waterproof | Not waterproof |

Advantages and Practical Benefits

- Superior resistance to tearing, compression, and impacts

- Supports heavier and fragile items securely

- Improves shipping efficiency and lowers replacement costs

- High adoption rate with 75% of companies reporting better shipping outcomes

- Eco-friendly with recycled materials aligning with sustainability goals

In our experience with eCommerce and manufacturing clients, durable cardboard significantly reduces product loss in transit while enhancing brand reliability.

What is a Paper Box?

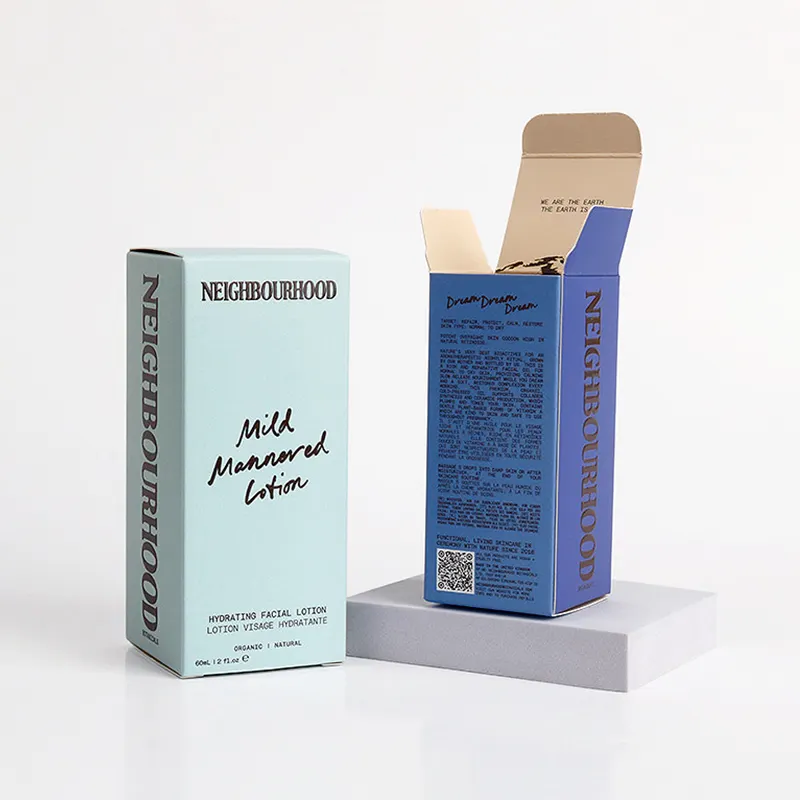

A paper box is a lightweight packaging container made from a single layer of thick paper-based material called paperboard. It is designed mainly for retail, 食べ物, or gift packaging where print quality and visual presentation are important, but it is not suited for heavy or high-impact shipping uses.

In our experience working with brands, 紙箱 stand out for their visual appeal and adaptability in design-driven markets. They are often chosen when print quality and branding are a primary concern, especially in retail and gift packaging sectors.

| タイプ | 材料 | Strength |

|---|---|---|

| 紙箱 | 単層板紙 | Supports up to 30 lbs |

| 段ボール箱 | Multi-layer corrugated or fluted board | Withstands 60+ lbs |

Paper boxes are ideal for lightweight goods where handling ease and aesthetics matter. Cardboard boxes, with their layered construction, deliver more durability for heavy shipments.

Cost, Print Quality, and Environmental Factors

| 側面 | 紙箱 | 段ボール箱 |

|---|---|---|

| Unit Cost | $0.30–$1.50 | $0.50–$2.00 |

| Print Quality | 光沢のある, high-quality surface | Printable but less refined |

| 持続可能性 | Often 100% recycled, 生分解性 | Recyclable, sometimes mixed material |

Brands aiming for high-impact visuals often opt for paper boxes despite slightly higher costs for premium finishes. Their strong environmental profile aligns with sustainable packaging goals.

Applications and Practical Considerations

- Popular for retail packaging, 食品パック, 高級品, and gift boxes

- Supports intricate die-cutting and high-end finishes

- Not suitable for heavy or highly fragile products during shipping

Choosing between a cardboard box vs paper box involves balancing cost, branding needs, and protection requirements. For products sold in-store or presented as gifts, paper boxes offer superior presentation value, while cardboard remains the go-to for transit durability.

Strength & 耐久性

Plastic boxes significantly outperform cardboard boxes in both strength and durability, offering superior resistance to moisture, 粉砕する, and environmental factors. Cardboard boxes are more prone to tearing, collapsing, and water damage, especially under heavy loads or in damp conditions.

In our experience working with packaging for eCommerce and manufacturing, the choice between plastic and cardboard impacts both product safety and total cost. Below, we examine key strength, 耐久性, reuse, and sustainability factors.

Comparison of Strength and Load Capacity

| 特徴 | Cardboard Box 📦 | Plastic Box 🛡️ |

|---|---|---|

| Load Capacity | Supports 9–30 kg (20–65 lbs) depending on wall strength | Supports own weight at higher stacking without collapse ✅ |

| Stacking Limit | Typically limited to 3 layers | Rigid interlocking design allows greater stacking heights |

| Structural Rigidity | Weaker, prone to crush under concentrated weight | Rigid walls prevent deformation |

Durability and Environmental Resistance

- Cardboard absorbs water easily, becoming soggy and losing structure under damp conditions.

- Plastic boxes are fully waterproof, shielding contents from moisture and humidity.

- Polypropylene and similar plastics can last for centuries without degrading.

- Cardboard suffers from pest damage, heat exposure, and wear from repeated handling; plastic resists most of these factors.

For supply chains exposed to varying climates, plastic boxes maintain consistent performance. Cardboard works for short-term indoor use but is risky in humidity-prone environments.

Reusability and Cost Considerations

| 側面 | 段ボール箱 | プラスチックの箱 |

|---|---|---|

| Reuse Cycles | Limited to a few uses before replacement | Can be reused hundreds of times without major wear |

| Initial Cost | Lower initial price | Higher upfront cost |

| Long-term Value | More frequent replacements increase total spend | Durability reduces replacement frequency for savings |

For businesses partnering with 百里紙包装, we advise weighing these points with your operational priorities. Our material expertise allows us to engineer cardboard solutions that maximize durability within ecological frameworks, keeping both performance and sustainability in balance.

Elevate Your Brand with Custom Eco-Friendly Packaging

Partner with Baili to create premium, sustainable paper boxes tailored to your unique brand identity. Experience seamless design, 生産, and quality assurance—all under one trusted roof.

材料 & Construction

Corrugated boxes have a three-layer structure with fluted middle layers between two liners, providing 30-60% higher compression strength and 2-3 times greater burst resistance than single-layer cardboard.

Packaging designers and manufacturers often evaluate cardboard and corrugated boxes based on how material structure impacts durability, 料金, そして持続可能性. 私たちの経験では, choosing between them depends on product fragility, shipping conditions, and brand presentation needs.

Material and Structural Differences

- Cardboard consists of a single-layer thick paper stock, offering a lightweight but less protective build.

- Corrugated boxes feature three layers: two linerboards with a fluted middle layer for added strength.

- Flutes come in standardized types (あ, B, C, E, F) affecting thickness and protection levels.

- Common corrugated types include single-wall, double-wall, and triple-wall configurations for different shipping demands.

Performance Comparison and Key Metrics

- Corrugated liners are typically Kraft paper (70-80% virgin pulp) or Test paper with more recycled content.

- Cardboard often contains recycled fibers, making it lighter but less durable.

- Corrugated boxes have an 89% recycling recovery rate and average 52% recycled content.

- Sustainable manufacturing includes renewable energy use and eco-friendly inks.

Application Suitability and Cost-Benefit Analysis

- Cardboard suits lightweight, non-fragile items and offers upfront cost savings.

- Corrugated is preferred for fragile or heavy products due to stronger protection and stacking ability.

- Although corrugated costs more initially, it reduces damage expenses and can be reused.

- Environmental trade-offs: Cardboard’s lighter transport impact vs. corrugated’s recyclability and reusability.

持続可能性 & リサイクル性

Paper and cardboard packaging generally outperform plastic alternatives in sustainability metrics, with recycling rates exceeding 70-80%, compared to plastic’s 40-50%. Paper-based materials have a much lower carbon footprint (~1% vs. 3.8% global emissions for plastic), though plastic may be more efficient for moisture-sensitive products due to weight and production energy advantages.

Packaging materials carry different impacts on the environment and supply chains. In our experience working with global brands, the best choice depends on the balance between recyclability, production efficiency, and product protection.

Key Sustainability and Recycling Comparisons

| メトリック | Paper/Cardboard | プラスチック |

|---|---|---|

| Recycling Rate | 70-80%+ (Netherlands 80%+) | 40-50%, only 7% reused into packaging |

| Global Carbon Footprint | ~1% of global emissions | ~3.8% of global emissions |

| Production Energy | Higher energy use, often renewable | ~40% less energy needed |

| Water Usage | Significant water consumption | Lower water use per unit |

| Reuse Cycles | Fibers recycled 5-7 times before degrading | Quality drops quickly, often downcycled |

| Biodegradability | Fully biodegradable | Persists as microplastics |

Optimizing Packaging Choice by Use Case

- Paper and cardboard excel for dry goods, single-use items, and lightweight e-commerce packaging.

- Plastic is ideal for moisture-sensitive, airtight, or long shelf-life products where reducing food waste is crucial.

- Hybrid packaging options (paper with biodegradable coatings, バイオプラスチック) help address moisture challenges.

- Weight influences environmental impact, with heavier loads increasing transport emissions.

- Matching product needs with regional recycling infrastructure leads to smarter, more sustainable choices.

FAQs About Cardboard vs. Paper Boxes

Are paper boxes eco-friendly?

Paper boxes are generally made from renewable fiber sources and often contain a high percentage of recycled content. When paired with water-based inks and coatings, they become an eco-conscious option for many brands.

私たちの経験では, integrating FSC-certified materials in paper box production supports both brand values and compliance with global environmental standards.

Can cardboard boxes be printed in full color?

はい, cardboard boxes can be printed with full-color designs using offset or digital printing methods. This allows for sharp graphics and branded visuals throughout the packaging surface.

We also offer advanced finishing such as foil stamping, エンボス加工, and spot UV to enhance the final presentation.

Which is cheaper for bulk orders?

For large-scale orders, folding paper boxes often have a lower unit cost compared to rigid cardboard boxes. This is due to reduced material thickness and lighter weight, which can also lower shipping expenses.

That said, corrugated cardboard may be more cost-efficient when higher durability is required for transit protection.

Which performs better in humid conditions?

Corrugated cardboard with moisture-resistant coatings generally outperforms standard paper boxes in humid or damp environments. The thicker fluted structure provides better rigidity and shape retention.

For long-distance or overseas shipping, adding a lamination layer can extend the life of either packaging type under humid conditions.

Can both be recycled?

Both cardboard and paper boxes are widely recyclable, provided they are free from excessive plastic lamination or food contamination. Recycling streams for these materials are established in most regions.

Opting for biodegradable coatings and avoiding mixed-material designs further improves recyclability rates.

最終的な考え

Across the comparisons, it’s clear that the right packaging choice comes down to balancing three factors: product protection, プレゼンテーション, そして持続可能性. Corrugated cardboard delivers superior strength and stacking stability for heavy or fragile goods, while paperboard excels in visual appeal, lightweight handling, and retail-ready versatility. Each material carries different cost structures, environmental impacts, and production efficiencies, making the decision highly context-dependent.

For packaging designers, eCommerce brands, and manufacturers, aligning material choice with product weight, shipping conditions, and brand goals can lower damage rates, control costs, and strengthen customer experience. Evaluating these trade-offs early enables more resilient supply chains and better margins. Partnering with paper box packaging supplier who understands both materials can help you design solutions that meet functional needs while reinforcing your brand’s environmental commitments.